1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

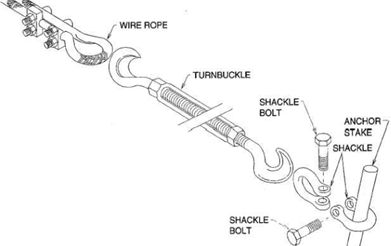

A greatly underused tool of wonderful convenience, turnbuckles have the ability to relieve you of a lot of stress during a challenging lift or rig. Primarily, turnbuckles are used when you need to increase or decrease tension in order to make minute adjustments to a load that are sometimes due to an off-set center of gravity. Turnbuckles can be used to make adjustments to help equalize the load and to correct that off-center of gravity.

Overall, turnbuckles provide a lot of versatility. Another example of a good use for turnbuckles are when a lift has six vertical picking points, which may require as minimal as a four-bar system. Any time this situation presents itself, it become difficult to ensure that you have equal load distribution amongst the six picking points. The worker has the option to place 4 (24 ft) slings on the four outside corners, which means on the two middle lugs, you can place another bar and utilize a shorter sling with a turnbuckle and allow you to adjust the tension to achieve equilibrium across all six lugs. Turnbuckles essentially pick up the slack on unbalanced loads.

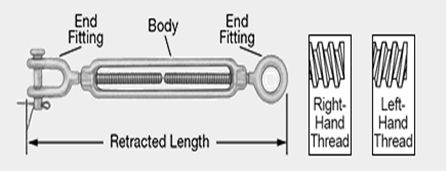

They consist of two threaded end fittings and a threaded body. One end fitting has right-hand threads (fitting tightens clockwise), and the other end has left-hand threads (fitting tightens counterclockwise). The turnbuckle body has matching right- and left-hand internal threads. Turning the turnbuckle body adjusts the end fittings an equal amount on each end.

There are six different combinations of turnbuckles including jaw and jaw, eye and eye, hook and hook, jaw and eye, eye and hook, and jaw and hook. The latter three can have their configurations be reversed, but they’re still essentially the same configuration despite being categorized differently. For example, jaw and eye and eye and jaw share virtually no difference between them save for how you visually read them from left to right.

TYPE:

Eye and Eye: Designed with a tear drop fitting on the end (akin to the appearance of a sewing needle eye), this configuration is intended for a shackle to be attached to it with a pin going through the eye. This is how you would attach the rigging to the turnbuckle. You would place a shackle on each end, which generally means you would have a sling, or other approved rigging attachments attached to the shackle and then you would install the turnbuckle.

Jaw and Jaw: This configuration is designed with a clevis or jaw end (resembles a“U” shape with a pin through it). These can be used in a few different ways. You can either attach the sling straight onto the end or you can have the clevis or jaw fit over a lifting lug and pinned to the lifting lug. Additionally, you can add a pin to a shackle. This configuration has a little more versatility as to how you can attach it to the load.

Jaw and Eye: You can also configure a jaw and eye together, which gives you more flexibility. However, this configuration isn’t as common to do unless you have a fixed point or a lug that’s difficult to work on a lift. You have to install that turnbuckle onto a jaw end and shackle the sling or the rigging onto the eye end.

Hook and Hook: Hook is an additional option that’s available to use. Typical uses are generally guy wire applications. Primarily, a worker will use a hook-configured turnbuckle in this application because it’s easier to install and tighten, which allow for the addition of a few more inches. However, hook configurations are far less practical due to the lack of a safety latch, which are a feature of jaw-end and eye-end configurations. Without a safety latch, you increase the risks associated with the lift and there’s nothing that can protect your load.

TURNBUCKLE U.S. TYPE, DROP FORGED

Made of galvanized steel, these turnbuckles have a thick coating for mild corrosion resistance.

Forged bodies and components are stronger than cast bodies and components.

Oval eyes provide more room to attach connectors.

Test load: Proof Load = SWL (WLL) x 2.5, Breaking Load = SWL (WLL) x 5

Surface: Hot Dip Galvanized

Reference: American society of testing materials, ASTMF 1145

ETC: Available certificate os NDT (M/T, U/T), 3rd Inspection test report

Special size, design and, another material can supply as your requirement.

CLOSED-BODY HOOK-TO-HOOK TURNBUCKLES (Extruded Aluminum Body with Zinc-Plated Steel Fittings)

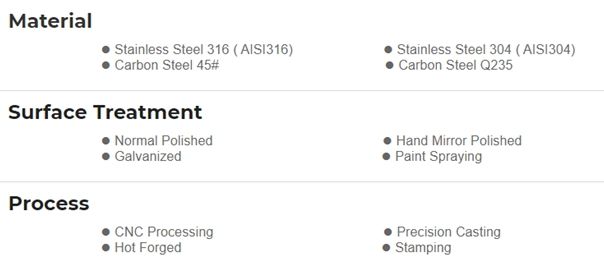

Closed body turnbuckles are a traditional style rigging screw body. Manufactured from high quality 316 grade solid stainless steel. Perfect for architectural and marine applications.

Zinc-plated steel is mildly corrosion resistant.

Aluminum is lightweight and has good corrosion resistance.

STAINLESS STEEL TURNBUCKLE

Material: AISI304 / AISI316

Product Description: Turnbuckle is the most widely used kind of rigging hardware and specifically suited for adjusting the tension and length of stainless steel wire rope, balustrade systems and other tension methods.

The closed body protects threads from damage and debris and has a slim profile to fit in tight spaces. Made of 316 stainless steel, these turnbuckles have excellent corrosion resistance.

Turnbuckles and their configurations simply offer a solution to a specific challenging lifting scenario. With any rigging or lifting selection, all the rigging is determined by the pieces of equipment that need to be lifted and by its other factors including headroom challenges, confined spaces, or any restrictions in moving a load or having offset center of gravity, as well.

For example, should you need to elevate something to four feet, your options are installing four, five, or six shackles in a line depending on the size of the shackles to make up the difference or you can install one turnbuckle and adjust it accordingly.