1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

Wire Rope Clips can have a lot of usage. They are a simple fitting that can be easily used in the field or shop.

Sometimes called a u-bolt,u-bolt clip or cable clip, they can be used to join two wire rope ends together, make an eye for a pulling application, or to secure the loose end of a wire rope after a wedge socket (or other appropriate device) has been used to terminate a crane’s hook.

But using clips to create wire rope slings for overhead lifting is NOT one of their many uses.

--QUOTE--:

ASME B30.9 states that wire rope clips shall not be used to fabricate wire rope slings, except where the application of slings prevents the use of prefabricated slings.

ASME B30.9 also calls for any wire rope clip application to be designed by a qualified person.

ASME B30.9 states wire rope clips shall be drop-forged steel of single saddle (u-bolt) or double saddle clip. Malleable cast iron clips shall not be used.

ASME B30.26 contains specific instructions for the use of wire rope clips.

OSHA 1926.251(c)(4)(iii) states: Eyes in wire rope bridles, slings or bull wires shall not be formed by wire rope clips or knots.

--UNQUOTE--

If you are working in General Industry applications, it restricts the use of wire rope clips to form eyes.

Why these restrictions?

Wire rope clips diminish the working load limit of the wire rope to generally about 70-75% of its original strength. There are better and more efficient ways to fabricate slings for overhead lifting.

For situations where use of wire rope clips are approved, it’s important to remember the proper way to install the clips. Incorrect installation can reduce the working load limit by 40% or more. The easiest thing is to remember, “never saddle a dead horse.”

Wire Rope Clip Safety Notice!

Under the approved Code of Practice for Load Lifting & Rigging,slings assembled with wire rope clips are not to be used for lifting.

To comply with manufacturer’s specification the correct number of clips must be installed correctly andtightened to the correct torque using a torque wrench. The correct installation technique is shown below.

IMPORTANT! CHECK BEFORE STARTING USE WIRE ROPE CLIPS!

Wire rope clips should be inspected before use to ensure that:

• all markings are legible;

• the wire rope clip is free from nicks, gouges and cracks;

• a wire rope clip with the correct dimension has been selected;

• never repair or reshape a wire rope clip by welding, heating or bending as this may affect the performance.

Instruction for correct use:

The wire rope clip should be fitted to the wire rope as shown in the

diagrams below.

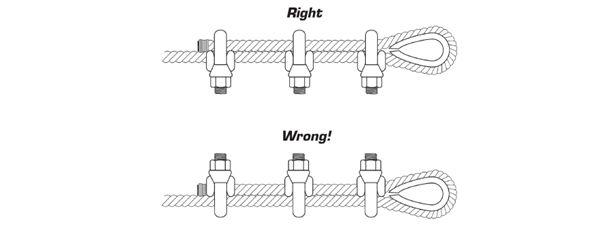

The bridge of the wire rope clip should always be placed on the load bearing part of the rope. The U-bolt ofthe clip should be placed on the rope tail, also known as the “dead end” of the rope.

Turn back enough wire rope length so that the required minimum number of clips can be installed according to the instructions below.

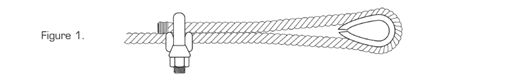

The first clip must be placed one bridge width from the turned back rope tail or dead end of the rope,according to figure 1. Tighten nuts to the specified torque.

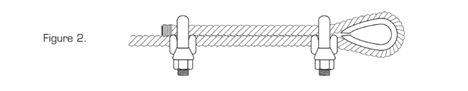

The second clip must be placed immediately against the thimble but nevertheless in such a position that thecorrect tightening of the clip does not damage the outer wires of the wire rope (figure 2). Tighten the nutsfirmly but not yet to the specified torque.

The following clips should be placed on the wire rope between the first and second clip in such a way that

they are separated by at least 1½ times the clip-width with a maximum of 3 times the clip-width according to figure 3.

Apply light tension on the rope and tighten all nuts evenly, alternating until reaching the specified torque.

During assembly and before the rope is taken into service, the nuts must be tightened once again to theprescribed torque. After the load is applied for the first time, the torque value must be checked again andcorrected if necessary. Periodically re-tightening of the nuts must be done at 10.000 cycles (heavy usage),20.000 e.g. every 3 months, 6 months, annually.

Wire rope clamps come in many different designs to fit any rigging application:

ZINC MALLEABLE WIRE ROPE CLIPS (Material: malleable iron)

ZINC CAST IRON WIRE ROPE CLIPS(Material: cast iron)

H.D.G. DROP FORGED WIRE ROPE CLIPS(Material: 45# steel)

FIST WIRE ROPE CLIPS(Material: 45# steel)

STAINLESS STEEL WIRE ROPE CLIPS(Material:stainless steel 304/316/316L)

Find more information in our website,pls click:

https://www.huahanmachinery.com/product/wire-rope-clips.html

In addition, for clips to work properly and gain their design efficiency, the proper number of clips is required and the nuts must be torqued as prescribed by the manufacturer. For more information on proper installation, check out this video from the Crosby Group.

https://www.youtube.com/watch?v=VvvSk-eLhJA

For Crosby’s complete application instructions check out this link: http://www.thecrosbygroup.com/wp-content/uploads/2013/12/56.pdf

If you have more questions on wire rope clips, comment below. Remember that Safety through Education is more than just our motto, it is our guiding principle. If you need training on proper application on any other rigging hardware, reach out to us. We are here for you.