1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

What is a wire rope clip?

Wire rope clip is otherwise known as a wire rope clamp, wire cable clamp, wire clamp, wire clip, U-bolt, etc. It is widely used for making eye-loop connections or join two wire rope cable ends together. The traditional styles of wire rope clips usually have three components: a U-shaped bolt, a forged or cast iron saddle, and two nuts.

A wire rope clip, sometimes called a u-bolt clamp or u-bolt clip, is used to clamp the loose end of a length of wire rope, once it has been looped back to form an eye. These fittings consist of a u-bolt and have a saddle secured by two nuts. Generally, wire rope assemblies need at least two or three wire rope clips to secure the ends properly to the length of the rope.

Drop forged wire rope clips vs. malleable wire rope clips

Wire rope clips are not designed to be used in an overhead lifting situation (swage sleeves should be used instead), drop forged wire rope clips are heavy-duty wire rope clips that can be used for sustaining overhead loads. Examples include guy lines, support lines, scaffolding, etc.

Drop forged clips are galvanized, meaning they have a heavy coating of a zinc solution that will hold up to worksite abuse and the elements for a long time. Drop forged steel are excellent for use as guy wire clamps for heavy-duty guying applications because they are both strong and resistant to corrosion.

Malleable Clips are a light-duty wire rope clip and are not for anything overhead. As the name “malleable” indicates, it is a softer wire rope clip, thus a lighter duty option. They can be used for fences and other applications that do not sustain loads overhead.

Overhead lifting vs. sustaining overhead loads

The ‘overhead lifting’ versus ‘sustaining overhead loads’ can be confusing, but a good rule of thumb to ask is: “Is the object being moved or being held in place?” If it is being moved, then wire rope clips are not to be used. If it is being held in place, then the next question is: Is it above ground (suspended from the ceiling, an awning, scaffolding, etc…) or will it be on a fence or on another object near the ground? If it is above ground, heavy-duty drop-forged is the best choice. If on a fence near the ground, malleable clips are acceptable.

It’s important to note that wire rope clips diminish the working load limit of the wire rope to generally about 80% of its original strength.

Wire rope clips materials

Wire rope clips are available in a variety of materials and finishes but basically three types of materials, carbon steel, cast, malleable iron, and stainless steel.

Carbon steel wire rope cable clamps are galvanized, or hot dipped galvanized, the galvanized metal wire clamp has an added zinc layer to prevent rusting and protect against scratching and the addition of carbon corresponds with an increase in the hardness and strength of wire rope cable clamps.Stainless steel wire rope clamps are the best choice for corrosion-resistant applications that can be used for saltwater environments.

How to install wire rope clips?

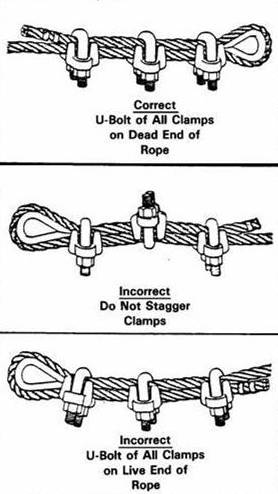

Commonly wire rope clamp installation is very simple, there’s a well-known saying can help you remember how to attach wire rope clips, that reads “never saddle a dead horse.” Just follow the recommendation ways:

· The dead-end of the wire rope (the end of the cut side) must be contacted with the U bolt, then the saddle should be on the live end.

· Keep three or more wire rope clips attached at the end of the wire rope dead end, space between each wire rope clip should be at least 6 times the wire rope diameter.

· Tighten the wire rope clip closest to the thimble eye loop as possible, and never start from the one farthest from eye separately first.

· You can see the correct and incorrect ways of installation from the following pictures and find how many wire rope clips to use at one wire rope loop.

How to use wire rope clips

Safety Notes: Always inspect wire rope for wear and abuse before applying wire rope clips. Apply wire rope clips over bare wire rope only. Use wire rope thimbles to protect the eye from being crushed and to prevent wear and abrasion on the rope. Never use a wire rope clip to directly connect two straight lengths of wire rope.

An important phrase to remember when applying a wire rope clip is “Never Saddle a Dead Horse”. This means you should never apply the saddle side of the clip over the dead end of the rope – the live end should always rest in the saddle.

Step 1.

Turn back the specified amount of rope from the thimble. Apply first clip one base width from the dead end of the rope. Tighten nuts evenly, alternating from one nut to the other until reaching the recommended torque.

Step 2.

If only two clips are required, apply the second clip as near the loop or thimble as possible. Remember, U-Bolt over dead end. Tighten nuts evenly, alternating until reaching the recommended torque.

When applying more than two clips, apply the second clip as near the loop or thimble as possible, turn nuts on second clip firmly, but do not tighten.

Step 3.

Space additional clips equally between the first two. Apply tension and then tighten the nuts on each clip evenly, alternating from one nut to the other until reaching recommended torque.

Find more information about wire rope clips :

https://www.huahanmachinery.com/product/wire-rope-clips.html