1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

Snaps—also known as snap hooks or spring hooks—are hooks with a spring snap in their ends to prevent the accidental unhooking of a rope, cord, or other target line. Snaps are a common but essential component in a huge range of industrial applications, from dog leashes to theatrical lighting.

. Snap Hooks

The traditional snap hook is perhaps the most common type. Snap hooks are equipped with a durable spring that allows for strong, quick attachment to a rope, cable, chain, or other line.

In its most basic form, a snap hook is a roughly question-mark shaped metal hook with a hollow section into which the spring-loaded closing bar is fitted. There will also be a small appendage that catches the snap hook and opens it when pressed with the thumb. Upon release of the knob, the gate snaps close by the spring’s action.

Snap hooks can come from a wide variety of source materials, such as brass, stainless steel, and die-cast zinc. They also can provide different functions, such as:

• Panic snaps. This snap type allows the attached rope or cable to be released almost instantly. Some panic snaps are specifically designed for horses and come with a ring that instantly releases anything attached to the snap.

• Fixed-eye snaps. These snaps have bases that are fixed in place. They are often used in the marine industry as boating attachments.

• All-purpose snaps. These snaps let the operator change lures/rigs quickly without the need to retie a line.

• Swivel-eye snaps. Swivel-eye snaps have an adjustable base that allows the spring to turn along its vertical axis.

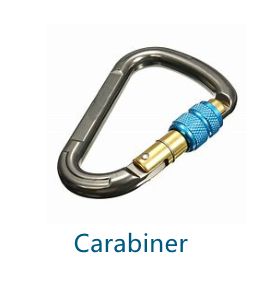

Snap Hook vs Carabiner

A carabiner is a metal loop with a spring-loaded entryway that will quickly open in order to detach a safety rig’s parts, such as the cable or line. The only way to open a carabiner is to manually push the gate away from the loop. This is one key difference between a carabiner and a more traditional snap hook—the snap hook can only release the cord or rope it holds if the spring gate is pushed towards the loop, instead of away from it.

Snaps vary in the amount of weight for which they are designed, and the amount of force they can successfully withstand without breakage. Snap hooks and carabiners should both have a kN (kilo-Newton) rating engraved on their spine. This is a rating for the force of gravity that the snap can successfully absorb.

.

Trigger Snaps

Trigger snaps are considered a specialized type of snap hook. The distinguishing feature of a trigger snap is the addition of a small lever onto the spring gate apparatus. The snap’s user can easily press the lever, which then causes the spring gate to retract inwards and release the attached line. In practice, this means that a snap operator can easily attach or detach from a line with one hand.

Moreover, the trigger snap is designed so that it will not open accidentally. Trigger snaps are used for handbags and purses, camera and binocular straps, and other fashion or accessory applications.

. Bolt Snaps

Bolt snaps are like trigger snaps in the sense that they can be easily operated with one hand. The main difference between the two snap types is the unlocking mechanism. Whereas a trigger snap utilizes a lever; a bolt snap employs a button that causes the spring gate to release when pressed.

Bolt snaps tend to be less secure than trigger snaps since accidental pressure on the release button could cause an unintended detachment from the line or strap.

Material

snap hooks are made of various materials to suit every day or dangerous industrial needs accordingly.

• Die Cast Zinc is one of the most common types of material. It’s non-toxic, reusable, and as a metal, it’s stronger than plastic or other reinforced polymers. It also self lubricates, which is vital for the bearing to continue working.

• Aluminum is one of the premium materials for making snap hooks. Universal, they are light but exceptionally strong snap with a swivel eye. The inside diameter of the eye is 16-20 mm. As the snap is made of the material used in the aircraft industry, the loading capacity of the snap hooks can be more than 400 kg. Ideal for leisure and outdoor activities and just as suitable for extreme conditions. The snap is easily opened and closed with one hand.

• Stainless Steel is highly resistant to all types of corrosion, making it ideal for outdoor use in all weather. It can endure many days of rain and high heat without losing any of its utility. It’s slightly heavier but not that much more expensive as a material, allowing it to find plenty of applications.

• Brass isn’t as strong as steel or as versatile as zinc, but it is naturally stylish. Well-polished brass stands out as a different metal and is best used on swivel hooks that might not serve a constant function. It’s seen as fancier, which can match up with interior projects or low-impact usage.

• Malleable iron is highly durable and tough, even in tiny degrees. It can make tiny but still very powerful hooks that stainless steel or die-cast zin would be hard to form in such small shapes. Malleable iron doesn’t lose nearly as much tensile strength when reduced in size, making it ideal for heavier uses and more delicate applications.

• Steel, just plain rough steel, is used for most industrial use. It doesn’t need to be fancy or good-looking. It just needs to do its job holding and supporting the high weight that spun on an axis at will.

What are Snaps Used For

Snaps can be used in a comprehensive array of industries and applications. Examples of common applications include:

• Sports equipment. Snap hooks can keep volleyball and tennis nets level and tight. Facility managers for baseball fields may use them to hold up the netting behind home plate. Snap hooks may also be used to secure rifle slings, bird straps, or water skis. The sports applications for snap hooks are almost limitless.

• Dog leashes. Dog leash snap hooks come in a wide variety and at different cost and quality levels. Factors to consider in choosing a snap hook type for dog leashes include: snap material, swivel-eye vs. fixed, eye shape, and eye diameter.

• Awnings. Whether an awning is retractable or stationary, stainless steel snap hooks and other snap types typically provide stable and adjustable support.

• Marine hardware. Sailors can employ snap hooks to attach to anchor chains, trailer safety chains, to secure equipment, or to secure vessels to docks.

But while snap hooks are usually thought of as heavy-duty hardware and associated with tough, durable products, the truth is that snap hooks have a softer side. There are many creative ways that snap hooks can be put to use.

Find more information about snap hook :

https://www.huahanmachinery.com/product/aluminum-snap-hooks.html