1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

Rope Material Properties and Use Cases

Rope is made by twisting or braiding multiple strands or yarns together to form a stronger and more durable material. Rope has long been an extremely important tool for humans, as it’s used for tying, binding, pulling, dragging, and lifting. The art of making rope is very old, but today, many people would much rather go to a hardware or outdoor store and purchase a length of rope than make it by hand, but it’s nonetheless a very useful skill to have. Rope can be made by hand or with the help of a machine, and it can be constructed from many materials, such as natural plant fibers, plastic, paper, strings, wires, or basically anything else that can be cut into strips.

Rope Material Properties and Use Cases

Polypropylene Rope

Polypropylene ropes are synthetic and possess a variety of unique qualities. Polypropylene rope is particularly suited for use around water and will not rot due to water and is resistant to mildew. This rope is also produced in a variety of colors making it a common choice for barriers at golf courses, parks or even power plants. Because polypropylene floats, it is used to designate swimming lanes in pools. Commercial fishermen commonly utilize this rope, especially in crab and lobster lines. It can also be used for buoy moorings, aquaculture, and net lines.

PROS & CONS

Positives: dielectric/insulator, floats, water resistant, lightweight, low-cost, UV resistant, color variety.

Negatives: stretches (although this could be a positive), susceptible to friction.

Most Common Uses: Work around electric lines, marine applications, swimming-lane barriers.

Extraordinary Qualities

Dielectric ability is an important quality of polypropylene rope. Should this rope touch a live electrical wire it will not conduct the electric current. Because polypropylene rope acts as an insulator, electricians and tree workers who work around live electrical wires use polypropylene rope. When using this rope for hauling or hoisting, attention should be given to any abrasions against the rope as it can melt from friction. Polypropylene also lacks stretch memory. When stretched, it will not return to its normal size.

This rope has wide capabilities. If you need a strong rope to be used in or around water, or if you anticipate possible exposure to electricity, then polypropylene rope will be your best choice.

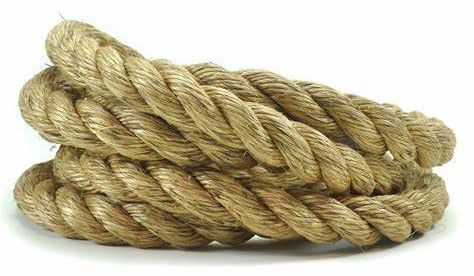

Manila Rope

The natural strength and all around utility of manila rope has made it the standard for quality rope. Manila rope consists of all-natural hemp fibers. This creates aesthetic appeal commonly used for decorative fences or other landscaping purposes.

Because of susceptibility to liquid absorption and UV decay, the user should be careful of sustained tension on the rope especially when exposed to the elements. Manila’s absorbing quality makes it the first choice for many physical activities that require direct handling of the rope. For purposes such as tug of war, climbing, obstacle courses, or stage rigging, manila rope absorbs perspiration providing better grip. This rope will not hazardously snap back when broken as other synthetic ropes may. For a quality natural rope that is aesthetically appealing and safe for active handling, manila rope is an excellent choice.

PROS & CONS

Positives: Visually appealing, snap-resistant, low-cost.

Negatives: Not UV or water resistant, may harden or rot over long periods of time.

Most Common Uses: Pulling, decoration, landscaping, rigging.

Nylon Rope

For superior strength and remarkable stretching capabilities, nylon is the rope of choice. Stronger than both manila and polypropylene, nylon commonly finds itself pulling the heaviest loads and bearing the most weight.

Having superior strength, nylon also maintains a smooth surface and its resistance to abrasion makes it ideal for pulley systems or winches. Also, different fall protection systems or rescue line assemblies are constructed from nylon rope. Within these applications, the strength and elasticity of nylon will be most beneficial.

PROS & CONS

Positives: Strong, smooth, abrasion resistant, UV resistant.

Negatives: Absorbs water, weakens in water.

Most Common Uses: Towing lines, anchor lines, pulleys, winches, tie-downs, fall-protection systems.

Extraordinary Properties

While both manila and polypropylene are susceptible to UV damage, nylon rope is resistant to UV, chemical exposure or any other form of rot. Despite the fact that water can weaken the strength of nylon, this effect is so slight that nylon is still commonly used for mooring lines and anchor lines. In fact, nylon rope is a great choice for any tie-down because of its strength, stretch, and sustenance in any environment. The all-around durability of nylon rope makes it useful for any job in any situation.

Polyester rope

Polyester is considered by some to be the best general purpose rope. It's also one of the more popular choices when a tough heavy duty rope is needed.

Polyester rope is a great rope for general industrial applications as well as rigging applications. It does great in the outdoors and tough elements of nature. Can be seen being used for lines to tie down or hold back boats in marine applications.

A few uses for this rope may include: winches, dock rigging, blocking, or simple household applications. It can also be mistaken many times as Nylon with many fine details in differences. Largest difference being it's resistance to chemicals.

PROS & CONS

Positives: Rot and UV resistant, retains strength when wet or dry and abrasion resistance.

Negatives: Bright white color can become discolored and brown/green in marine applications.

Most Common Uses: Rigging, winches, general household uses.

Find more information about rope:

https://www.huahanmachinery.com/rope01.html