1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

How To Use Ratchet Straps

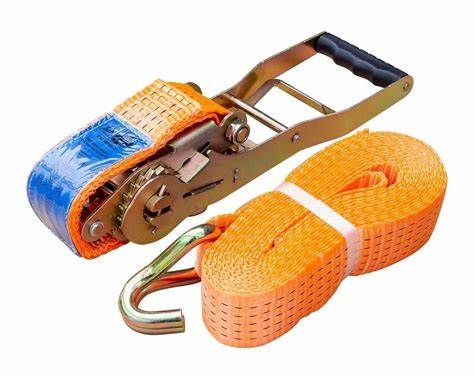

WHAT IS RATCHER STRAPS

Ratchet straps are cargo tie-down straps made of polyester webbing. They are run through a buckle that lets you loosen and tighten the strap, so you can lengthen the strap until you can pull it across your entire load, then tighten the strap until there’s enough tension to secure the load. Occasionally, we are asked how to use ratchet straps and what straps are for.

Ratchet straps can tie down a load by securing it to the floor of a flatbed truck. They can also be used to tie down and secure a piece of cargo to the sides of the interior of an enclosed trailer. It can connect to anchor points in the side of a flatbed truck, like D-rings, and can also latch onto anchor points on the floor of the truck bed for easy tightening and are essential flatbed trailer accessories for heavy-duty cargo securement.

RATCHET STRAP CONSTRUCTION

To understand how this equipment works, you first have to look at what ratchet straps are made of. The most commonly-offered material is polyester, although other fabrics like nylon are available. Polyester has the strength and low stretchiness necessary to ensure the safety of your haul for your whole trip. Other benefits of polyester include resistance to UV rays, mildew, mold, and many common chemicals.

TIE DOWN STYLES

Because there are so many possible applications, ratchet straps are available in a diverse selection of styles. When choosing the right one for you, there are several factors to consider.

WIDTH

The first is the strap width. This has a huge impact on the working load limit (WLL) of a ratchet strap. This rating is incredibly important – it lets you know exactly how much weight that piece of rigging is capable of securing. Using a ratchet tie down strap with an inadequate WLL can lead to damaged cargo, increased risk of personnel injury, and other safety hazards.

You calculate WLL by dividing the break strength (BS) – the point at which the strap will fail – by three, and is dependent on the lowest-rated strap component. For example, if the strap is rated for 3,000 lbs. but the end fitting is only rated to 2,500 lbs., the WLL will be 2,500 lbs.

You’ll find information like WLL and break strength included on a tag that comes attached to the ratchet strap.

Strap widths are generally available between 1” and 4”:

1” straps are generally used for light-duty applications, with a WLL of up to around 1,000 lbs.

2” straps are the most commonly-used option because they are available with E- and L-track compatible hardware. Their WLL can be up to 3,333 lbs.

3” and 4” straps are the optimal choice for heavy-duty tie down applications. The 3” strap has a WLL of around 5,400 lbs., while the 4” strap is 5,400 lbs. and above!

END HARDWARE

Another factor involves the end hardware. As mentioned above, some end fittings work with E-track and L-track. Other options include wire hooks, chain ends, and more – all with slightly different application suitability.

The end hardware you choose will generally be informed by the type of attachment points you have (or plan to have) in your trailer, as well as your available space. For example, you might choose a wire hook if your attachment point is in a narrow, harder-to-reach space.

ASSEMBLY TYPE

The last factor we will cover is assembly type - choose from full or endless. The full assembly consists of two sections, one with an end fitting and a ratchet, and the other with an end fitting and a fixture-less end. These two straps thread together to create your tie down. A full assembly is the standard pick for most applications, as it allows for more versatility in your setup.

The endless assembly is frequently used to bundle items together, as it consists of just one strap with a ratchet and a fixture-less end. You simply feed the fixture-less end through the mandrel to create a solid loop, then ratchet it to secure.

Polyester has the strength and low stretchiness necessary to ensure the safety of your haul for your whole trip. Other benefits of polyester include resistance to UV rays, mildew, mold, and many common chemicals.

Unlike winch straps, ratchet straps do not require your truck to have trailer winches installed along the sides. You shouldn’t discredit winches, though! Winches wind and unwind your polyester webbing straps, so they can be useful for some projects. For more information about winch straps, go through the details of winch straps.

When compared to winch straps and ratchet tie-down straps can be secured independently to any kind of anchor point on the floor or side of your trailer. This makes them preferred among most flatbed truckers. You can use them whenever you need to secure a piece of cargo for transport.

Always make sure your load doesn’t exceed the straps’ working load limit before you begin hauling. If it does, you might have to use multiple straps in short length-wise intervals to disperse the tension enough to secure the load safely. Or, it may be more appropriate to use a winch strap or a G70 chain to secure your cargo, rather than a ratchet strap.

1.Use the release catch to open the ratchet. The release catch, also known as the release lever, is a smaller handle that disengages the ratcheting handle. It’s located in the center of the top movable piece of the ratchet. Pull up the release catch and flip the ratchet fully open. Set the open ratchet on a table before you so that the spiked wheels (cogs) are facing upwards.

2. Thread the strap through the bottom of the ratchet. The slot at the bottom of the ratchet, known as the “mandrel,” holds the length of the strap. To thread the strap, start from underneath the ratchet and push it up through the mandrel. The threaded strap should then lay straight, the length of it overlapping with the second strap on the other side of the ratchet.

3. Continue feeding the strap through the mandrel until it feels taut. Remember that you can always tighten it with the ratchet later, so don’t worry too much about the length.

1.Pull and hold the release tab. This will override the ratcheting function and release the lock. The release tab should be easy to access and located on the top of the ratchet.

If you can’t locate the release tab, check your operation instruction manual.

2. Open up the ratchet and pull the strap loose. Flip the ratchet completely open so it lays flat, then pull on the non-fixed side of the strap. This will release the strap from the ratchet’s hold and allow you to completely remove the strap.

3. Pull and hold the release tab to close the ratchet again. Locate the release tab once again and hold it down while you flip the ratchet closed. This will keep the ratchet in locked position until it is ready to be used to again.

Find more information about ratchet straps :

https://www.huahanmachinery.com/ratchet01.html