1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

Are you planning your next overhead lifting project and need to specify the type of sling and rigging equipment you’ll be using? While it’s important to understand the best type of sling to use, it’s just as important to select the right type rigging hardware that will be connected to that sling. Choosing the right type of lifting hook that can be used will be determined by a number of different factors.

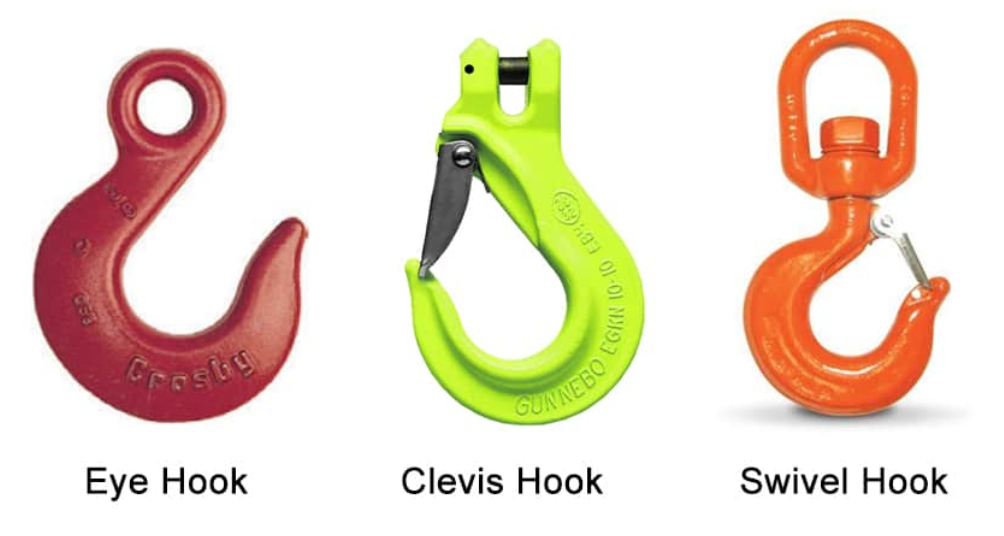

In this article, we’ll discuss the different type of sling hooks that exist, including: eye hooks, clevis hooks, swivel hooks, hooks with latches, sorting hooks, foundry hooks, j-hooks, grab hooks, and barrel hooks.

In order to understand the best type of hook to use with your sling, you need to understand the following:

The total weight of the load

The type of load or material you will be lifting

The type of sling being used

The type of sling hitch being used

The connection to the load – will you be using shackles or does the load have engineered lifting points?

The number of lifting points and overall distance between the lifting points

The sling angle

we offer all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, hoist parts, and engineered below-the-hook lifting devices. Our goal for this article is to help you select the right type of sling assembly for your future lifting and rigging needs.

If you’re looking for more information on the advantages/disadvantages between wire rope, chain, and synthetic slings, we also have an article on how to choose the best lifting sling for your application.

Lifting Hook Types, Uses, and Design

There are two main ways a lifting hook or sling hook can be attached to the sling—you can either use a hook with an eye at the top, or with a clevis at the top to make your connection to the sling. There are also hooks that have a bearing or bushing at the top that swivels. We’ll dive a little deeper into all three of these styles below:

Eye Hooks

On an eye hook, a chain or fittings are welded for a permanent connection to the sling. With an eye hook, you get far more flexibility in terms of movement and ergonomics to position the hook and attach it to the load. However, an eye hook is a permanent solution—if the throat of the hook becomes stretched, cracked, or bent during use, the whole sling would have to be failed out upon inspection and removed from service.

Clevis Hooks

A clevis fastener is a fastener system consisting of a clevis and clevis pin. The clevis is a U-shaped piece that has holes at the end of prongs to accept the clevis pin. The clevis pin is similar to a bolt, but is only partially threaded or unthreaded with a cross-hole for a split pin. A clevis hook is a hook, with or without a snap lock, with a clevis and bolt or pin at the base. The clevis is used to fasten the hook to a bracket or chain.

Some rigging shops and end users who are not certified to weld alloy chain slings, utilize clevis hooks to make a mechanical connection to a chain sling. The advantage of a mechanical connection is that if a clevis hook becomes damaged due to stretch, bending, or cracking, it can easily be removed and replaced without scrapping the entire chain sling. If this occurs on a chain sling, this is considered a repair to the sling and must be proof-tested prior to the sling being put back into service.

Also, a clevis hook can pivot side to side for positioning when connecting to a load, but doesn’t have the same flexibility or freedom of movement that an eye hook does.

Swivel Hooks

There are two types of swivel hooks and the user should be aware of the type of swivel hook that they’re using prior to lifting a load into the air:

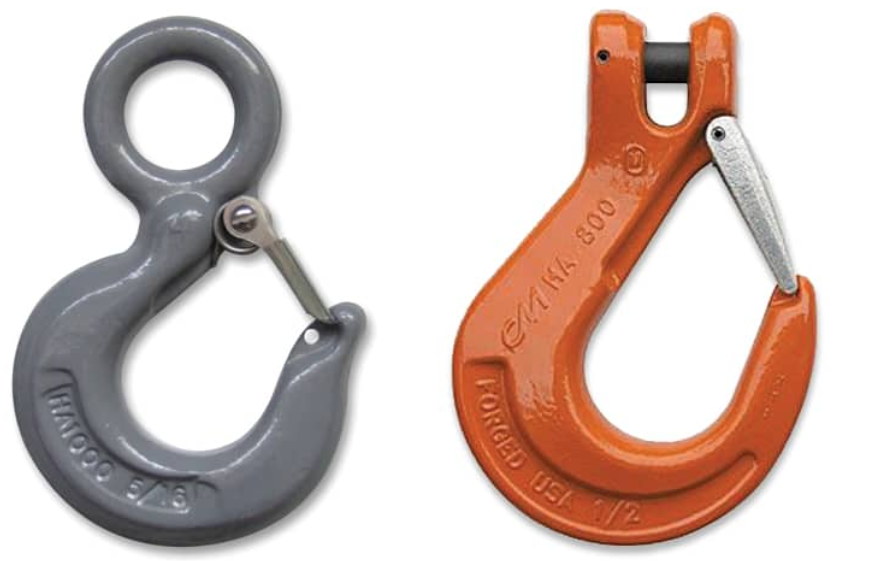

Lifting Hooks With Latches

When deciding on whether to use a hook latch or not, careful consideration must be given to the specific lifting application. The use of latches on hooks is a topic that is constantly up for debate in the lifting and rigging industries. While some people argue that hook latches are always required and should always be utilized, others argue that latches are not required.

Unfortunately, there are limited explanations or interpretations of when a latch on a hook must be utilized. With no clear industry-wide rules on whether a hook latch is required on a crane hook or a sling hook, the decision is ultimately left up to the owner or end-user.

We advise that the end user must evaluate the work activity with regards to the safety of their employees. If the activity makes the use of the latch impractical, unnecessary, or more dangerous, then the end user may choose to eliminate the latch. It is also recommended that each lifting activity is considered independently as far as the use of a hook latch is concerned.

Sling Hooks With Self-Closing Latch Kits

All hook manufacturers make products with or without latches. Some hooks are compatible with self-closing latch kits.

There are two types of hooks that rarely utilize a latch assembly due to the nature of the lift or the environment where the lift is being performed:

A sorting hook will never utilize a latch kit. They’re typically being utilized for lifts with tip loading or where a latch would limit the practical use when lifting plates and cylindrical loads (such as pipe) where full throat engagement is required.

A foundry hook rarely utilizes a latch kit because they’re often used in environments or applications where there is a clear danger for a worker to reach up to connect the load or remove the load from the hook.

The one disadvantage of a hook with a self-closing latch is that they have a much shorter life span than a positive latching hook. One thing to consider when buying a hook with a latch kit is to understand if it’s an imported or domestically-made product.

Imported rigging products are attractive because they’re often less expensive than a domestically-made product. However, if the latch breaks on an imported hook, it can be very difficult, or expensive, to find a replacement latch kit. You may even wipe out the initial cost-savings by having to buy a completely new hook because you can’t source the replacement latch kit.

Self-Locking Hooks

A self-locking hook is a hook with a latch that is a more robust and engineered component of the hook. The advantage of a positive latching hook is that it’s nearly impossible to break the latch on these hooks and once it closes, it can’t open again until the load is released from the hook.

These types of hooks are close to standard on chain slings because they’re more robust and can handle heavier-duty environments and lifts where chain is the preferred sling medium.

Grab Hooks

Grab Hooks are designed with a special narrow throat used to “grab” and shorten or hold a length of chain used in overhead lifting applications. The throat engages the chain between the links for quick non-slip handling. There are two types of grab hooks, so the end-user should understand what type of grab hook they’re using prior to lifting a load into the air:

Standard grab hook – When shortening a sling leg using a standard grab hook, you need to reduce the Working Load Limit by 20%. These standard grab hooks are popular because they’re less expensive than a cradle grab hook.

Cradle grab hook – The belly of a cradle grab hook is casted like a hammock for a piece of chain to lay in. Generally speaking, if you shorten a length of chain using a cradle grab hook, you have 100% of the Working Load Limit.

Learning more hook information, pls click below:

https://www.huahanmachinery.com/product/hooks.html