1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

What are shackles and how are they used?

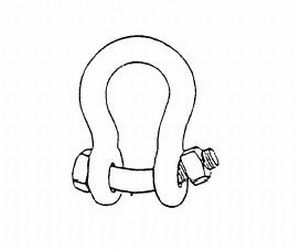

A shackle, also known as a gyve, is a U-shaped piece of metal secured with a clevis pin or bolt across the opening, or a hinged metal loop secured with a quick-release locking pin mechanism. The term also applies to handcuffs and other similarly conceived restraint devices that function in a similar manner. Shackles are the primary connecting link in all manner of rigging systems, from boats and ships to industrial crane rigging, as they allow different rigging subsets to be connected or disconnected quickly. A shackle is also the similarly shaped piece of metal used with a locking mechanism in padlocks. A carabiner is a type of shackle used in mountaineering.

What Are the Different Types of Shackles?

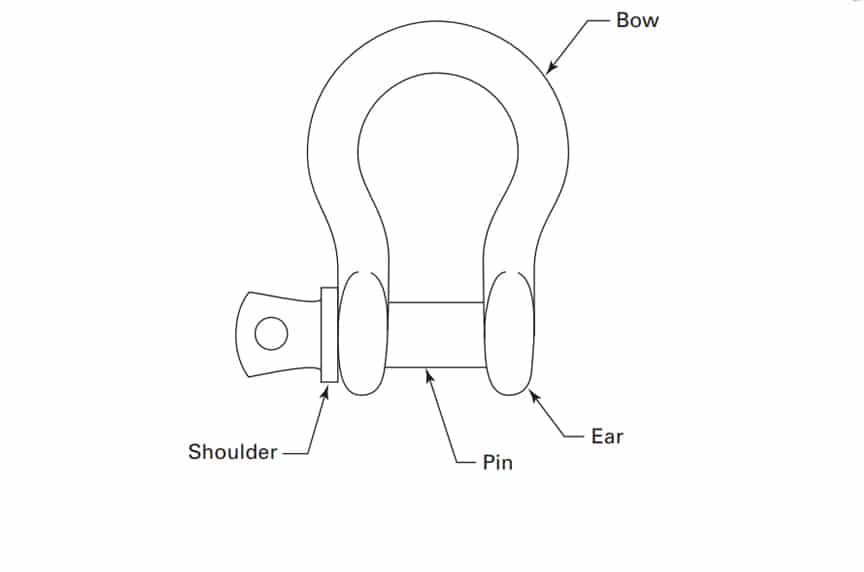

The Parts of a Shackle:

Before we begin, let’s identify the different parts of a shackle so when we use terms like “bow,” “ears,” “pin,” or “shoulder,” you’re familiar with what we’re referring to:

Bow – the curved portion of the shackle body opposite the pin—often referred to as the bail, body, dee, or bowl

Ears – portion of the shackle body that support the shackle pin

Pin – a steel bolt made to span the two shackle ears

Shoulder – the part of the pin that makes contact against the ear when the pin is fully threaded or engaged

Always ensure that the shackle that you select meets or exceeds the working load limit for the task at hand and is comparable to the Working Load Limit (WLL) of the slings and other rigging hardware being used.

Shackle Bow Types: Anchor Shackles vs. Chain Shackles

The shape of the shackle’s body, or bow, is a major determination in the style of the shackle and how it can be used.

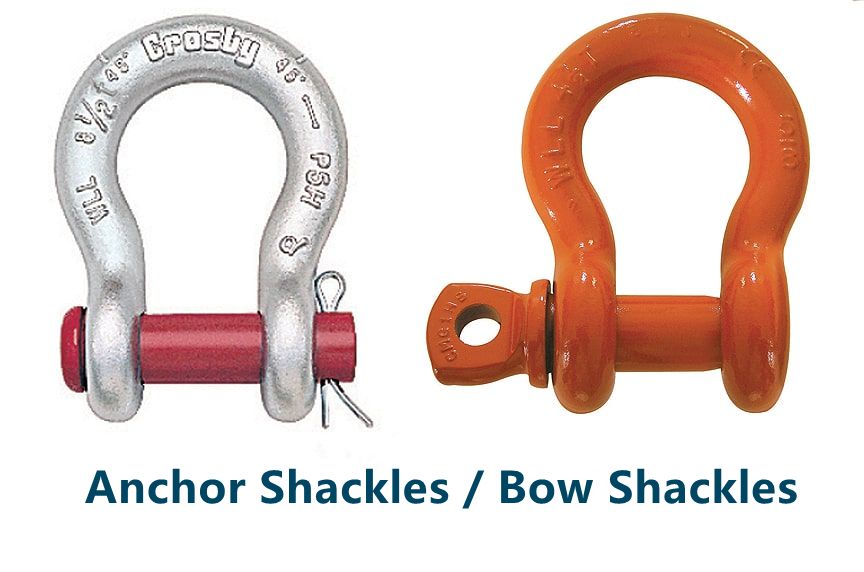

Anchor Shackles / Bow Shackles

The terms anchor shackles and bow shackles are both used interchangeably and refer to a type of shackle with a larger, round “O” shaped bow. A larger bow shape allows these types of shackles to be side loaded or used in multiple sling-leg connections.

Anchor shackles can be used for side pulling when you factor in the reduction to the WLL based on the angle deviation from in-line (0°)—which we will discuss in more detail later in this article.

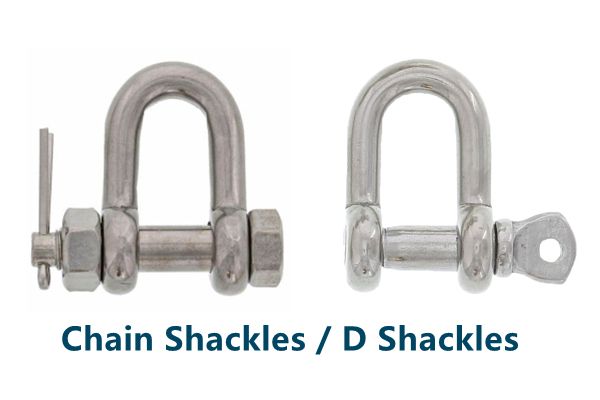

Chain Shackles / D Shackles

Chain shackles, also referred to as D shackles, have a D-shaped bow that is narrower than anchor shackles. Because these shackles are designed and rated for in-line tension, they should not be side loaded, as side loading can twist or bend the bow of the shackle.

When using a chain shackle, the center line of the load should always coincide with the center line of the shackle when in use.

Shackle Material

Carbon Steel Shackles

Design Factor of 6:1. More ductile than alloy. Available in round pin, screw pin, bolt type.

Alloy Steel Shackles

Design Factor of 5:1. Stronger than carbon steel. Can achieve an equivalent WLL as carbon shackles in a smaller product design. Available in round pin, screw pin, bolt type.

Galvanized Shackles

The galvanization process adds a thin layer of zinc oxide to protect against rust and corrosion. Galvanized shackles can be used in industrial applications where moisture isn’t a primary concern, but where the shackles still need to be protected against elements that may cause accelerated corrosion or deterioration to the product.

Stainless Steel Shackles

Stainless steel shackles provide the greatest corrosion resistance and are ideal for marine applications. Varying grades of stainless steel can be used to protect the shackle against salt water or chemical environments. Shackles made from stainless steel are typically more expensive than galvanized shackles.

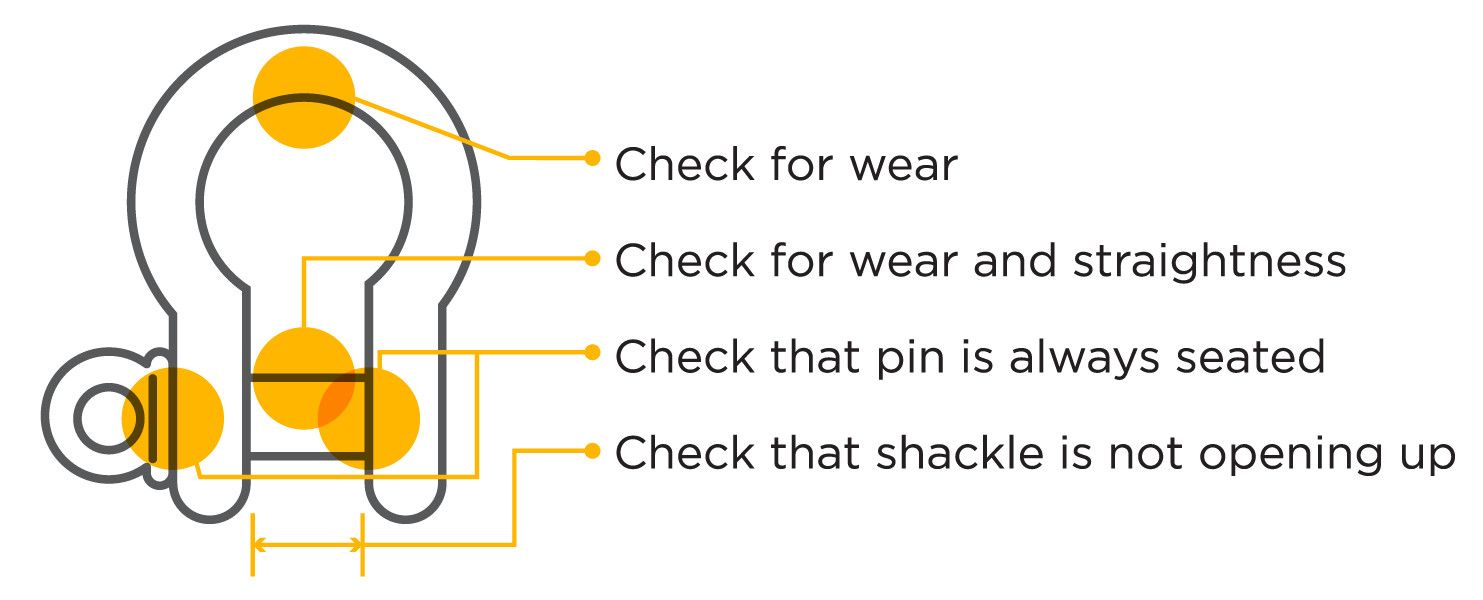

How should you inspect shackles?

Inspect shackles regularly.

Inspect the shackle eye and pin holes for stretching (elongation) and wear. Elongation means the metal is being overloaded.

Inspect the shackle body for bending. A bent shackle indicates excessive side-loading.

Inspect all shackle pins for distortion, surface blemishes, wear and fractures.

All pins must be straight and all screw pins must be completely seated.

Replace shackles that are bent, show excessive wear by more than 10% of the original diameter, or have an elongated eye or shackle pin holes.

What should you avoid when using shackles?

Do not replace the shackle pin with a bolt or unidentified pins. A load will bend the bolt.

Do not allow a shackle to be pulled at an angle. The legs will open. Pack the pin with washers to center the shackle.

Do not use screw pin shackles or fit pins in contact with moving parts if the pin can roll and unscrew. If the load shifts, the sling will unscrew the shackle pin.

Do not use round pin shackles restrained only by a cotter pin for overhead lifting.

Do not use shackles with bent pins or deformed bodies.

Do not force, hammer or wedge shackles into position.

Do not exceed 120 degrees for the angle when using multiple leg slings.

Find more information about Chain Hoists :

https://www.huahanmachinery.com/shackle01.html