1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

What is a wire rope thimble?

Wire rope thimbles also known as cable thimbles, are used for making reinforce loop(eyelet) with grips, clips or clamps by preventing fraying caused by friction at the bearing anchor point to protect and extend the service life of the wire rope or sling. They are just one of the many types of wire rope fittings (ferrules, wire rope clips, terminals, etc.).

Wire rope thimbles are used in wire rope assemblies to keep an eye from being crushed.

When a wire rope assembly is terminated with an eye or loop at the end, a cable thimble is inserted to form the eye of the loop before the rope is secured. Steel thimbles (or stainless steel thimbles in high corrosive environments), offer added protection from wear and tear of direct contact and deformation of the eye, extending the service life of the Wire Rope or Wire Rope Sling.

It's important to note that break strength is typically not denoted on steel rope thimbles as the pressure on the thimble eye can vary depending on tension and direction the pressure comes from.

Types of wire rope thimbles

Galvanized Light Duty Thimble & Galvanized Heavy Duty Thimble

Thimbles come in two different duty grades, Light Duty and Heavy Duty.

Light duty thimbles are typically used in static applications such as a permanent installation, a controlled environment, or in situations where they won’t experience much load.

Light Duty Thimble Wire Rope & Heavy Duty Light Duty Comparison

Light duty thimbles typically work best on traditional fiber rope because they can handle the same amount of load and rough handling as you would expect a fiber rope to take. You can see here that this light duty thimble is ideal for this application, while this heavy duty thimble is grossly oversized.

Heavy Duty ThimbleHeavy Duty Thimble Assembly

Because heavy duty thimbles have extended protective material around their edges, and a tendency to resist deformation in uncontrolled applications, they are commonly used in applications that will experience dynamic loading, or loads near or at the working load limit. Heavy duty thimbles are ideal for lifting, towing, and applications that will require the user to frequently connect and disconnect the thimble to other rigging components

Zinc Coated Thimble & Stainless Thimble

When choosing a thimble for your application, it’s important to consider what type of environment the thimble will be used in. Zinc Plated Steel, Hot Dipped Galvanized Steel, and Type 316 Stainless Steel.

Starting with the most corrosion resistant, stainless steel thimbles are best suited for being used in outdoor applications and are highly resistant to rust. Stainless Steel thimbles are also ideal for being used in or near saltwater environments where corrosion frequently occurs, and are the best choice when using stainless steel cable or chain.

Our heavy duty, hot dipped galvanized thimbles come in at a lower cost than stainless steel, and are also suited for outdoor environments. While galvanized components are also ideal for outdoor use, galvanized components can exhibit signs of surface rust if the galvanized coating is worn off on the load bearing or contact areas of the component, this type of surface rust is normally worn off when loaded or used, and shouldn’t affect the component’s performance.

Our light duty zinc plated thimbles can also be used outdoors, but it’s important to be aware that a zinc coating is thinner than a hot dipped galvanized coating, so the thimble may exhibit signs of rust earlier than a hot dipped galvanized thimble, this is especially true in environments where the thimble will be exposed to rain or snow, or in salt air or salt water environments.

Wire rope thimble installation

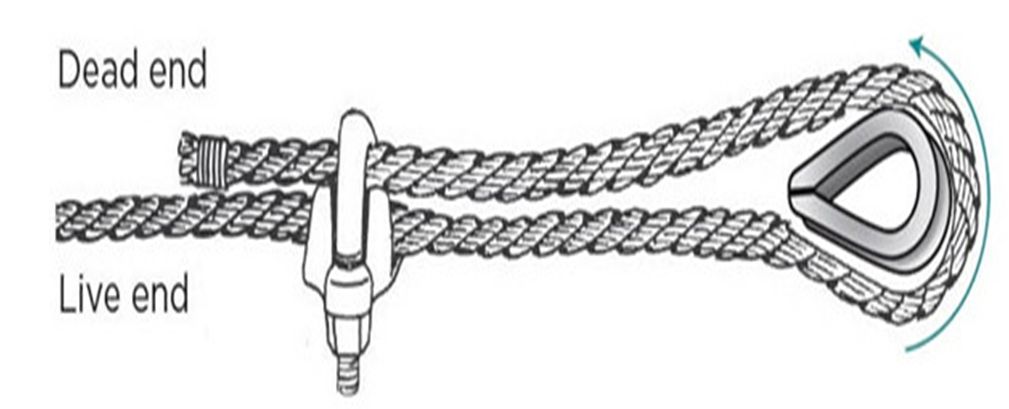

Step 1

Simply wrap the end of the wire rope around the outer groove of the thimble, lace the dead end of the wire rope past the U-bolt of the wire rope grips or a wire rope ferrule crimp to hold onto the bearing anchor point at the end of the thimble to prevent fraying caused by friction.

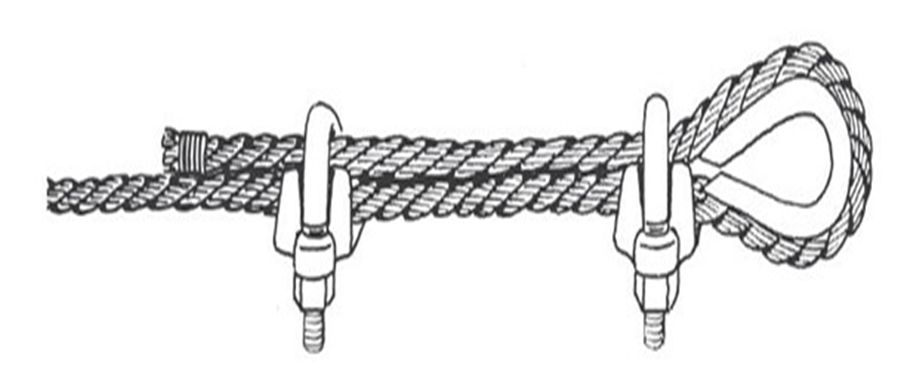

Step 2

Once in place, put another wire rope clip as near the loop you just wrapped over the thimble. Turn nuts firmly but do not yet tighten to the proper torque, we recommend using a crimping/swaging tool to compress the ferrule firmly onto the rope to hold your thimble loop securely.

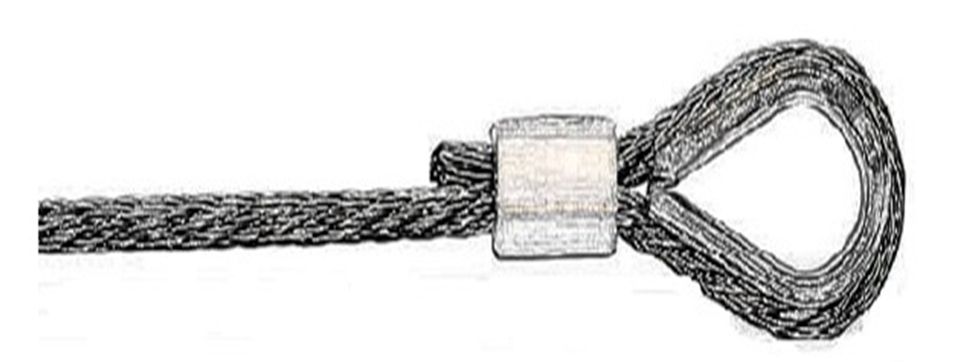

Alternatively, you can use a wire rope ferrule crimp to secure your thimble in place. this method is quick and easy to install. For further information on installation using a wire rope ferrule please – click here

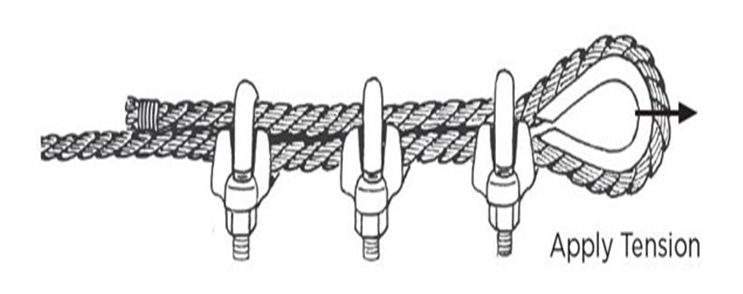

Step 3

Apply all other wire rope clips, spaced equally

between the first two, tighten them securely with an adjustable wrench to recommended torque. They should be 6-7 rope diameters apart.

How to use wire rope thimble?

Wire rope thimbles are used in conjunction with cable and rope to protect the eyes and will allow for smooth rope guiding around natural curves. So that the most important thing is to make sure the thimble eye securely fastened. Here are some tips for correctly using wire rope thimble:

1. To know the right rope thimble size to the cable, for example when you are using 1/2″ uncoated rope cable, use a 1/2″ wire rope thimble.

2. Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized rigging fittings.

3. While you are using a vinyl coated cable, you should multiply the actual size of the cable, usually use a larger size thimble than normal, for the actual diameter is the thickness of the vinyl coating plus the inside wire rope diameter. For example, if you are using a 5/16″ vinyl coated cable that is coated to 3/8″ diameter, you’d want to use a 3/8″ wire rope thimble

Find more information about wire rope thimble :

https://www.huahanmachinery.com/thimble01.html